Fluid Dynamics Research Apparatus (Flow Zone)

Senior Capstone Design Project

Sep. 2023 - May 2024

To aid the scientific research conducted by Evanston Township High School (ETHS), I project managed and led a group of seven other Northwestern mechanical engineers in designing, manufacturing, and developing an apparatus for the students to research fluid dynamics.

Skills:

-

RAM and GANTT Charts

-

Weekly Status Reports

-

Organized Internal Meetings and Agendas

-

Solidworks CAD

-

Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) with Ansys

-

Designed for Assembly and Cost Analysis

-

Manufactured using Carpentry and 80/20 Components

-

SLA and FDM 3D Printing

-

Experiment Data Analysis with Google Sheets

Since our client required our device to produce a specified smooth flow for radial hydraulic jumps, I headed the development of a flow straightener nozzle with narrow channels. The nozzle is divided in two to allow students to customize the outlet geometry via their school’s FDM printer.

_edited.jpg)

_edited.png)

Flow Straightener Nozzle

.png)

With Channels

.png)

No Channels

We conducted CFD on the nozzle fluid body connected to a tube to justify how the narrow channels reduce turbulent kinetic energy. We compared our design to one without channels using a quarter of the fluid bodies to reduce computational power.

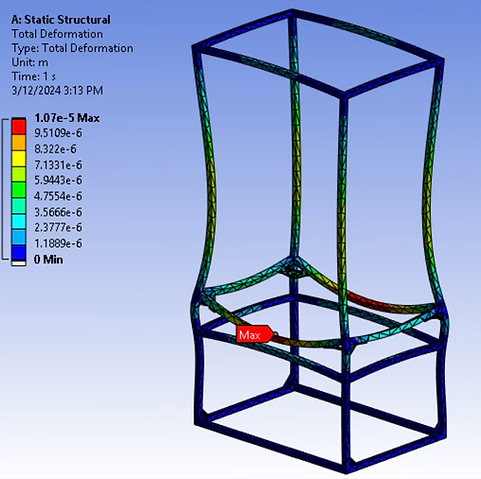

We also developed the main frame of the apparatus to house multiple nozzles along with other fluid components (i.e pumps, valves, flow meters, and tubing). I headed our final design of our alpha prototype using 80/20 components, conducting FEA to ensure it could handle expected loads. We studied the total deformation and equivalent stress.

.png)

Completed Housing

.png)

.png)

Total Deformation

.png)

.png)

Equivalent Stress

.png)